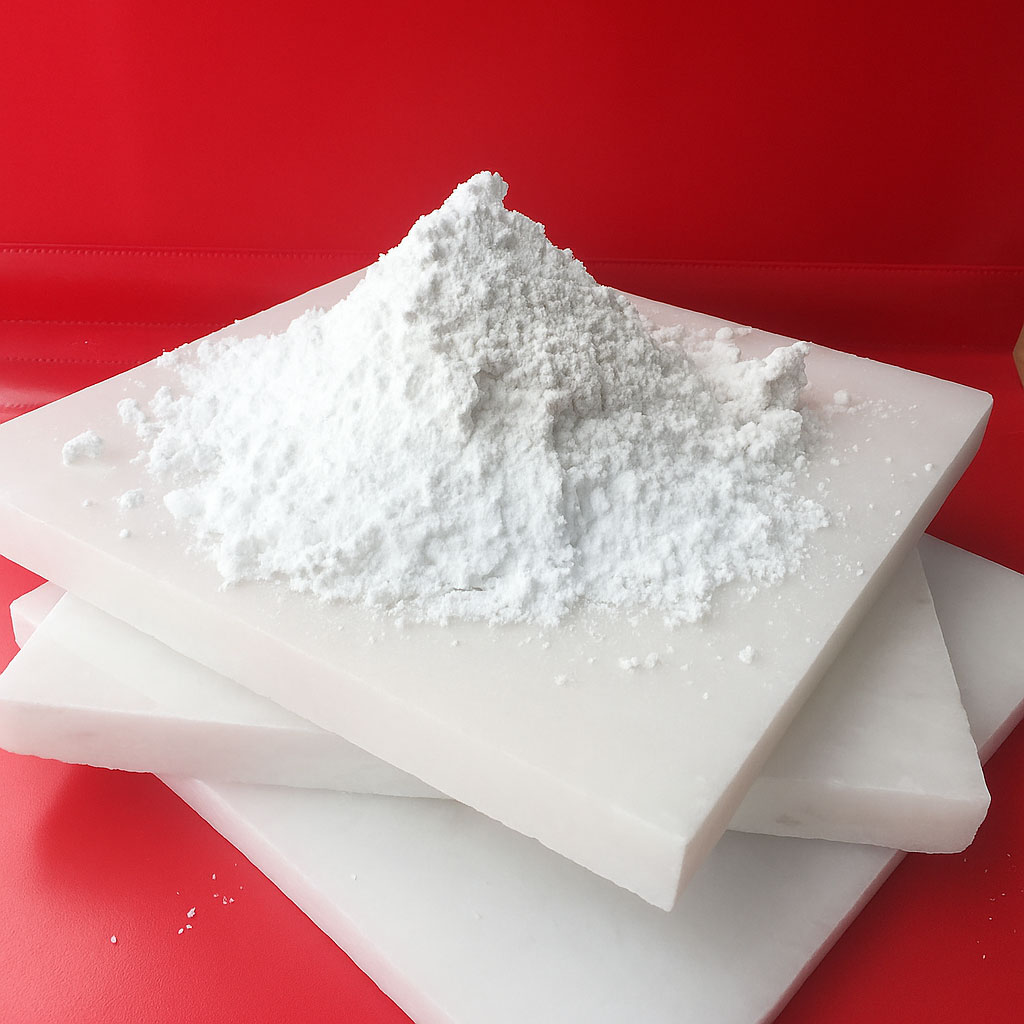

CHINESE MACHINE COATED STONE POWDER PRODUCTS

Contact

- Product Code: LAHP249

- Views: 274

Forced heat coating system combined with dual separation produces stable pellets, uniform coating, reduced oil absorption and increased resin compatibility. Suitable for Taical resins, recycled pellets and cost-effective applications.

| Specifications | Typical value |

|---|---|

| Production line | Hydraulic crusher – Taiwan technology |

| Surface coating technology | Hot stearic acid spray + forced mixing |

| Productivity (estimated at THNA) | ~5,000 – 6,000 tons/month |

| Average particle size (D50) | 4 – 6 μm |

| Maximum particle size (D97) | ≤ 15 μm |

| Whiteness (ISO) | ≥ 98% |

| Brightness (Hunter L) | ≥ 96% |

| CaCO₃ content | ≥ 98.5% |

| Stearic acid coverage ratio | 0.8 – 1.2% |

| Surface coverage | 97 – 98.5% |

| Oil Absorption | 18 – 23 g/100g (reduced compared to uncoated goods) |

| Humidity | ≤ 0.20% |

| pH | 8.3 – 8.8 |

| Dispersion in plastics | Good – suitable for PP, PE, PVC |

| Colors | Fine white powder, even color |

| Typical applications | Taical plastic, plastic pipes, common plastic granules |

| Packaging | PE/PP bag 25kg or Jumbo bag 1,000kg |